Single-phase motors are widely used in household appliances and small industrial applications due to their simplicity and reliability․ They operate on a single-phase power supply, making them ideal for residential and light commercial settings․ These motors require additional components, such as capacitors, to start and run efficiently․ The capacitor provides the necessary phase shift to generate torque, enabling the motor to start and operate effectively․ This combination of simplicity and efficiency makes single-phase motors a popular choice for applications like fans, pumps, and refrigerators․

1․1 Overview of Single-Phase Motor Applications

Single-phase motors are widely used in residential and industrial applications due to their simplicity and versatility․ They power devices like fans, air conditioners, refrigerators, and pumps․ In industrial settings, they drive machine tools, small compressors, and conveyor systems․ Their compact design and low cost make them ideal for applications where three-phase power is unavailable․ These motors are also energy-efficient and require minimal maintenance, making them a preferred choice for both domestic and commercial uses․

1․2 Importance of Capacitors in Single-Phase Motors

Capacitors are essential for the operation of single-phase motors, enabling them to start efficiently․ They create a phase shift in the current, generating a rotating magnetic field necessary for motor rotation․ The capacitor provides the initial energy boost required for starting, improving starting torque and reducing current draw․ Without a capacitor, the motor would not start or run efficiently․ This component is critical for overcoming inertia and ensuring smooth operation in single-phase systems․

Understanding Capacitor-Start Motors

Capacitor-start motors use a capacitor and centrifugal switch to provide high starting torque․ The capacitor creates a phase shift, enabling the motor to start efficiently and smoothly․

2․1 What is a Capacitor-Start Motor?

A capacitor-start motor is a type of single-phase induction motor that uses a capacitor to create a phase shift in the current, enabling high starting torque․ It operates by connecting a capacitor and an auxiliary winding in parallel with the main winding during startup․ Once the motor reaches a predetermined speed, a centrifugal switch disconnects the capacitor, allowing the motor to run as a standard single-phase motor․ This design provides efficient starting and high torque for applications requiring quick acceleration․ The capacitor-start motor is widely used in appliances like air conditioners and refrigerators due to its reliability and performance․

2․2 Function of the Start Capacitor

The start capacitor in a single-phase motor creates a phase shift in the current flowing through the auxiliary winding, generating a high starting torque․ By storing electrical energy and releasing it during startup, the capacitor ensures the motor begins rotation efficiently․ Once the motor reaches approximately 70-80% of its rated speed, the centrifugal switch disconnects the capacitor, allowing the motor to run normally․ This component is crucial for initiating motion in applications where high starting torque is essential, such as compressors and pumps․

2․3 Role of the Centrifugal Switch

The centrifugal switch is a critical component in capacitor-start motors, ensuring proper operation during startup and runtime․ Activated by centrifugal force, the switch disconnects the start capacitor once the motor reaches approximately 70-80% of its rated speed․ This prevents overheating and allows the motor to run efficiently․ The switch operates automatically, ensuring the capacitor is only active during startup, making it essential for the motor’s performance and longevity in applications like pumps and compressors․ Its reliable operation is vital for smooth motor functioning․

Wiring Diagram Basics

A wiring diagram provides a visual representation of electrical connections, ensuring proper installation and troubleshooting of single-phase capacitor-start motors․ It uses standardized symbols and color codes to illustrate components and their relationships, simplifying the understanding of circuitry for technicians and installers․

3․1 Key Components of the Wiring Diagram

A wiring diagram for a single-phase capacitor-start motor includes essential components like the main winding, auxiliary winding, start capacitor, centrifugal switch, and power supply lines․ Symbols represent terminals, connections, and circuit paths, while color coding distinguishes live, neutral, and earth wires․ The diagram also shows the capacitor’s connection to the auxiliary winding and the centrifugal switch’s role in disconnecting the capacitor once the motor reaches operational speed․ These elements ensure proper motor operation and safety, guiding technicians through installation and troubleshooting processes effectively․

3․2 Reading and Interpreting the Diagram

Reading a single-phase capacitor-start motor wiring diagram involves identifying symbols, connections, and components․ Locate the main terminals, auxiliary windings, and start capacitor․ Trace the circuit to ensure proper power flow from the supply to the motor․ Note the color coding for live, neutral, and earth wires․ Verify the capacitor’s connection to the auxiliary winding and its disconnection via the centrifugal switch․ Cross-reference with the component list for accuracy․ Always follow safety guidelines and manufacturer instructions for reliable installation and troubleshooting․

3․3 Safety Considerations

When working with single-phase capacitor-start motors, safety is paramount․ Always de-energize the circuit before handling components․ Capacitors store high-voltage charges, so discharge them using a resistor․ Ensure proper grounding to prevent shocks․ Use insulated tools and wear protective gear․ Avoid short circuits, as they can cause damage or injury․ Follow manufacturer guidelines for voltage ratings and wire sizing․ Regularly inspect wiring for signs of wear or damage․ Never bypass safety devices, and ensure all connections are secure before powering up․ Always consult a licensed electrician if unsure․

Types of Capacitor-Start Motors

Capacitor-start motors are categorized into types like capacitor-start and capacitor-run motors, each offering distinct performance characteristics․ Dual voltage capacitor-start motors are also available, enhancing versatility in applications․

4․1 Capacitor-Start Motors vs․ Capacitor-Run Motors

Capacitor-start motors use a capacitor only during startup to create a phase shift, providing high starting torque․ Once running, the capacitor is disconnected by a centrifugal switch․ Capacitor-run motors, however, use the capacitor continuously to improve efficiency and reduce current․ While capacitor-start motors excel in high-torque applications, capacitor-run motors offer better energy efficiency but lower starting torque․ Understanding these differences is crucial for selecting the right motor for specific wiring diagram configurations and operational needs in single-phase systems․

4․2 Dual Voltage Capacitor-Start Motors

Dual voltage capacitor-start motors are designed to operate at two different voltage levels, typically 120/240V․ These motors feature separate windings for each voltage, allowing flexible installation․ The wiring diagram shows connections for both voltages, with the capacitor and centrifugal switch integrated accordingly․ Dual voltage motors are ideal for applications requiring adaptability, such as equipment used in different regions or systems with varying power supplies․ This design enhances versatility but may require additional wiring considerations to ensure proper operation at both voltage levels․

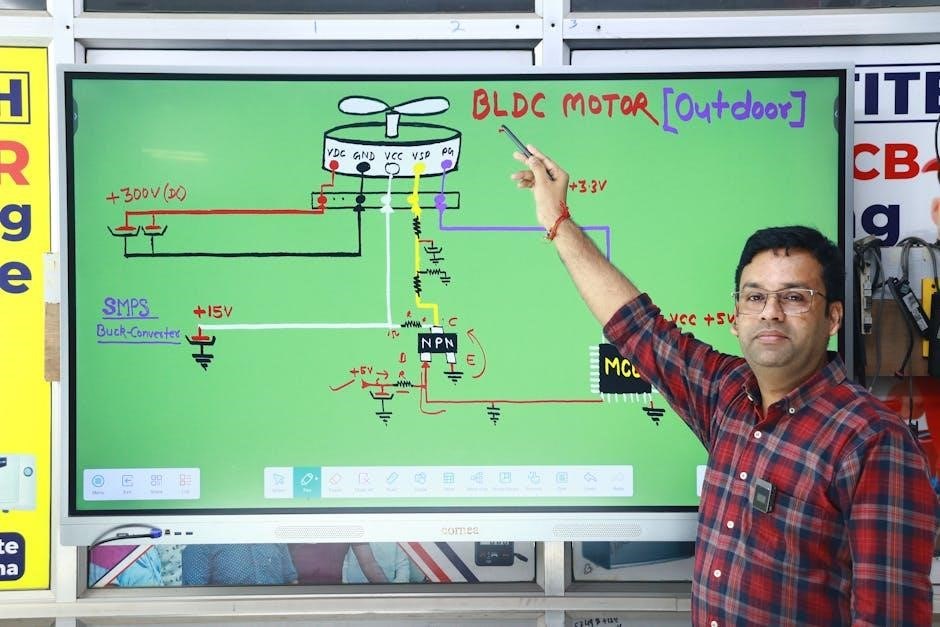

Capacitor Start Motor Wiring Diagram

A capacitor-start motor wiring diagram illustrates the connections for main and auxiliary windings, capacitor, and centrifugal switch․ It ensures proper power supply and starting torque․

5․1 Main and Auxiliary Windings Connection

The main and auxiliary windings are connected in a specific configuration to enable the motor’s operation․ The main winding is directly connected to the power supply, while the auxiliary winding is connected through a capacitor․ This setup creates a phase shift between the currents in the two windings, generating the necessary starting torque․ The windings are typically made of copper wire and are designed to handle the motor’s voltage and current requirements․ Proper connection ensures efficient operation and prevents motor damage․ Always refer to the wiring diagram for precise connections․

5․2 Capacitor and Centrifugal Switch Integration

The capacitor and centrifugal switch are essential components in a capacitor-start motor․ The capacitor is connected in series with the auxiliary winding to create a phase shift, enabling high starting torque․ The centrifugal switch automatically disconnects the auxiliary winding once the motor reaches operational speed, ensuring efficient running․ Proper integration of these components is crucial for smooth startups and preventing unnecessary power consumption․ This configuration guarantees reliable operation and optimal performance in single-phase motor applications․ Always follow the wiring diagram for accurate connections․

5․3 Power Supply Connections

Proper power supply connections are critical for the motor’s operation․ Connect the live wire to the main winding terminal, and the neutral wire to both the auxiliary winding and the centrifugal switch․ Ensure the capacitor is correctly linked between the auxiliary winding and the switch․ Double-check the wiring diagram for accurate connections, as incorrect wiring can damage the motor․ Always disconnect the power supply before making adjustments and verify connections with a voltage tester․ Follow the manufacturer’s guidelines for a safe and reliable setup․

Application-Specific Wiring Diagrams

This section covers wiring diagrams tailored to specific applications, such as residential fans and pumps, as well as industrial machinery and gearboxes, ensuring optimal performance in each context․

6․1 Residential Applications (Fans, Pumps)

In residential settings, capacitor-start motors are widely used in ceiling fans, water pumps, and air conditioning units․ The wiring diagram for these applications typically includes the main and auxiliary windings, a start capacitor, and a centrifugal switch․ Proper connections ensure high starting torque and smooth operation․ Safety guidelines must be followed to avoid electrical hazards․ Diagrams often highlight live, neutral, and earth wires, ensuring correct installation․ This setup optimizes performance for household devices, providing reliable operation under varying loads․ Always refer to manufacturer-specific PDF guides for precise configurations․

6․2 Industrial Applications (Machine Tools, Gearboxes)

In industrial settings, capacitor-start motors are essential for driving machine tools, gearboxes, and heavy-duty equipment․ The wiring diagram ensures robust performance under high load conditions․ Industrial motors often require dual voltage capabilities, and the diagram must account for this․ Key components include the centrifugal switch, start capacitor, and thermal overload protection․ Proper grounding and phase sequencing are critical for safe operation․ Industrial applications demand precise torque control, making the capacitor’s sizing and wiring crucial․ Always adhere to safety protocols to prevent electrical hazards in harsh environments․

Troubleshooting Common Issues

Identify symptoms like motor failure, overheating, or abnormal noise․ Check power supply, capacitor condition, and wiring connections․ Test for short circuits or open windings promptly․

7․1 Motor Not Starting

If the motor fails to start, check the capacitor for damage or incorrect rating․ Ensure proper wiring connections and verify the centrifugal switch operation․ Test the capacitor using a multimeter for capacitance or short circuits․ Inspect the power supply for correct voltage and ensure the start capacitor is engaged․ Check for blown fuses or tripped breakers․ Verify the motor windings for continuity and ensure the start winding is properly connected․ Consult the wiring diagram to confirm all connections match the manufacturer’s specifications․

7․2 Motor Overheating

Motor overheating can result from overloading, poor ventilation, or incorrect capacitor sizing․ Check for blockages in cooling vents and ensure proper airflow․ Verify the motor is not overloaded by comparing the load to its rated capacity․ Inspect for loose connections or wiring issues that cause excessive resistance․ Ensure the centrifugal switch disengages the start capacitor once running․ Monitor ambient temperature and compare it to the motor’s rated operating range․ Refer to the wiring diagram to confirm connections match the manufacturer’s specifications for optimal performance and heat management․

7․3 Capacitor Failure Symptoms

Capacitor failure can cause the motor to malfunction or fail to start․ Common symptoms include a buzzing or humming noise, reduced performance, or the motor not running at all․ The capacitor may swell physically, indicating internal damage․ Check for voltage drops or electrical leaks using a multimeter․ Ensure the capacitor matches the motor’s specifications for voltage and capacitance ratings․ Replace the capacitor if it shows signs of failure․ Always refer to the wiring diagram to confirm proper connections and ratings for safe operation and optimal performance․

Dual Voltage Motor Wiring

Dual voltage motors can operate at two different voltages, such as 120V and 240V, offering flexibility for various applications․ The wiring involves configuring the motor’s windings to match the selected voltage․ This typically requires adjusting the connections between the main and auxiliary windings, often through taps or voltage selectors․ The capacitor and centrifugal switch must also be appropriately integrated to ensure proper starting and running․ Always refer to the manufacturer’s wiring diagram for specific voltage configurations to avoid damage and ensure optimal performance․

8․1 Understanding Dual Voltage Requirements

Dual voltage motors are designed to operate efficiently at two different voltage levels, such as 120V and 240V․ This flexibility is achieved by reconfiguring the motor’s windings to suit the desired voltage․ The main and auxiliary windings are connected in series or parallel to match the voltage requirements․ The capacitor and centrifugal switch must also be compatible with the selected voltage to ensure proper starting and running․ Understanding these requirements is essential for safe and efficient motor operation across different power supply systems․ Always consult the manufacturer’s specifications for precise configurations․

8․2 Wiring Diagram for Dual Voltage Motors

A dual voltage motor wiring diagram illustrates how to connect the motor for either 120V or 240V operation․ For 120V, the main and auxiliary windings are connected in parallel, while for 240V, they are connected in series․ The start capacitor is placed in series with the auxiliary winding to provide the phase shift needed for starting․ The diagram also shows how the centrifugal switch disengages the capacitor once the motor reaches full speed․ Always refer to the manufacturer’s manual for specific configurations to ensure safe and proper installation․

Installation and Maintenance Tips

Proper grounding and secure connections are essential․ Regularly inspect capacitors and ensure tight wiring․ Use appropriate tools and follow safety standards for optimal performance and longevity․

9․1 Step-by-Step Installation Guide

Start by ensuring the site is prepared with proper tools and safety gear․ Connect the power supply to the motor terminals, following the wiring diagram․ Install the capacitor and centrifugal switch correctly, ensuring secure connections․ Mount the motor firmly to prevent vibration․ Double-check all wiring for accuracy and tighten connections․ Test the motor at low voltage to confirm operation․ Finally, ensure proper grounding and follow safety protocols for a safe and efficient setup․

9․2 Regular Maintenance for Optimal Performance

Regular maintenance is crucial to ensure the motor operates efficiently․ Inspect the capacitor for signs of wear or leakage and replace it if necessary․ Check wiring connections for tightness and damage․ Clean the motor to prevent dust buildup and ensure proper ventilation․ Lubricate bearings as recommended by the manufacturer․ Monitor operating temperatures and address any overheating issues promptly․ Replace worn-out components to maintain performance and extend motor lifespan․ Schedule periodic checks to identify potential issues early and prevent unexpected failures․

Resources and References

Consult official manufacturer websites, technical forums, and educational platforms for detailed guides, wiring diagrams, and troubleshooting tips specific to single-phase capacitor-start motors․

10․1 PDF Guides and Manuals

Download comprehensive PDF guides and manuals from reputable sources like manufacturer websites, academic institutions, or electrical engineering platforms․ These resources provide detailed wiring diagrams, installation steps, and troubleshooting tips for single-phase capacitor-start motors․ They often include schematics, component specifications, and safety guidelines․ Look for manuals specific to your motor brand or model for accurate information․ These PDFs are invaluable for DIY enthusiasts and professionals ensuring proper setup and maintenance of capacitor-start motors․

10․2 Manufacturer-Specific Diagrams

Manufacturer-specific diagrams are essential for accurate single-phase motor wiring․ These diagrams, often found in product manuals or official websites, provide precise wiring layouts tailored to the motor’s design․ They include details like terminal connections, capacitor ratings, and safety protocols․ Always refer to the manufacturer’s guide for your specific model to ensure compliance with design specifications․ This ensures proper installation, optimal performance, and adherence to safety standards, minimizing risks of malfunction or electrical hazards․

10․3 Online Tools and Tutorials

Online tools and tutorials are invaluable for understanding single-phase motor wiring․ Websites like AllAboutCircuits and Electrical Engineering Portal offer detailed guides and interactive simulations․ YouTube channels dedicated to electrical engineering provide step-by-step tutorials; Tools like LTspice allow users to simulate motor circuits before physical implementation․ These resources are particularly useful for troubleshooting and ensuring proper wiring configurations․ They cater to both beginners and experienced technicians, offering practical insights and visual aids for better comprehension․

Advantages and Limitations

Capacitor-start motors offer high starting torque, making them ideal for heavy-duty applications like pumps and compressors․ However, they may not be suitable for frequent start/stop cycles due to capacitor wear․

11․1 High Starting Torque Benefits

Capacitor-start motors deliver exceptional starting torque, crucial for heavy-duty applications requiring rapid acceleration․ This high torque ensures reliable startups, even under load conditions․ It enhances efficiency and reduces the risk of stalling, making these motors ideal for compressors, pumps, and industrial equipment․ The robust starting capability minimizes wear and tear on mechanical components, extending equipment lifespan․ This feature is particularly advantageous in scenarios where consistent performance and quick startups are essential for operational efficiency and productivity․

11․2 Limitations in Frequent Start/Stop Applications

Capacitor-start motors face limitations in applications requiring frequent start/stop cycles․ The repeated switching action can lead to accelerated wear on the centrifugal switch and capacitor degradation․ Prolonged cycling increases heat buildup, reducing component lifespan․ This makes them less suitable for applications like conveyors or machinery with intermittent operation․ Continuous cycling can also cause premature motor winding failures, emphasizing the need for alternative motor types in such scenarios to ensure reliability and longevity․

Frequently Asked Questions

Explore common queries about capacitor-start motors, troubleshooting tips, and clarifications on myths surrounding their operation and wiring, ensuring a deeper understanding of their functionality․

12․1 Common Queries About Capacitor-Start Motors

Users often ask about the role of capacitors, wiring diagrams, and troubleshooting․ Common questions include how to identify the correct capacitor size, interpreting start and run windings, and resolving issues like motor hum or failure to start․ Additionally, queries about dual voltage configurations and the purpose of the centrifugal switch are frequent․ These questions highlight the importance of understanding the motor’s electrical circuit and its components for proper installation and maintenance․

12․2 Addressing Misconceptions

A common misconception is that all single-phase motors require a capacitor to run, which is untrue․ Only capacitor-start and capacitor-run motors need them․ Another myth is that a larger capacitor improves performance, but it can damage the motor․ Some believe these motors are too complex for DIY projects, but with the right wiring diagram and precautions, they can be managed․ Understanding these facts helps in avoiding errors and ensures safe, efficient motor operation․