Clamps and saws are essential tools in woodworking and metalworking, ensuring safety and precision. They help achieve professional results by effectively holding and cutting materials in various projects.

1.1 Importance of Clamps in Woodworking

Clamps are indispensable in woodworking, ensuring materials remain stable during cutting, gluing, or joining. They prevent movement, promoting precise cuts and even bonding. Essential for projects requiring accuracy, clamps hold pieces firmly, reducing warping and ensuring professional results. Whether using C-clamps, bar clamps, or spring clamps, they are vital for securing workpieces, enabling precise cuts, and maintaining safety in the workshop. Their role is crucial in achieving clean, accurate, and professional finishes in woodworking projects.

1.2 Role of Saws in Cutting Materials

Saws are versatile tools essential for cutting various materials like wood, metal, and plastic. They provide precise cuts, enabling accurate project execution. Hand saws offer manual control, while power saws deliver speed and efficiency. Saws are crucial for achieving clean edges and proper fits in woodworking and construction. Their ability to handle different materials makes them indispensable in workshops. Proper sawing techniques ensure safety and professional results, making saws a cornerstone of effective material processing in both small and large-scale projects.

Types of Clamps

Clamps are essential tools for securing materials, offering stability and precision. Various types cater to different needs, ensuring effective handling in woodworking and metalworking projects.

2.1 Spring Clamps

Spring clamps are versatile tools designed for temporary holding. They feature a spring mechanism that provides quick and easy clamping, ideal for small projects. These clamps are lightweight and portable, making them perfect for holding materials in place during gluing or joining. Their adjustable jaws allow for a secure grip on various materials, ensuring stability. Spring clamps are a must-have for any workshop, offering convenience and efficiency in numerous tasks.

2.2 C-Clamps

C-Clamps are heavy-duty tools offering a strong grip for various materials. Made from durable metals like steel, they are ideal for woodworking and metalworking. Their adjustable design allows for securing materials of different thicknesses. The screw mechanism provides precise control, ensuring a tight hold. C-Clamps are versatile and commonly used in projects requiring stability. Regular maintenance, such as lubricating the screw, ensures optimal performance. They are a reliable choice for professionals and DIYers alike, delivering consistent results in demanding tasks.

2.3 Bar Clamps

Bar clamps are versatile tools featuring a long, rigid bar and a sliding jaw, making them ideal for large-scale projects. Their extended reach allows for clamping wide materials securely. Common in woodworking, they provide even pressure distribution, preventing warping. Adjustable bars accommodate various project sizes, while the ergonomic handles offer comfortable use. Bar clamps are essential for tasks like gluing and assembling furniture. Regular maintenance, such as cleaning and lubricating moving parts, ensures longevity. Their durability and flexibility make them a valuable asset in any workshop or project setting.

2.4 Panel Clamps

Panel clamps are specifically designed for holding large, flat materials like panels or sheets. Their wide surface area ensures even pressure distribution, preventing warping. Featuring adjustable arms and soft pads, they protect delicate surfaces while maintaining a strong grip. Ideal for tasks like gluing and assembling, panel clamps are versatile and essential for woodworking projects. Durable materials, such as steel, ensure longevity, while ergonomic handles provide comfort. Regular maintenance, like lubricating moving parts, keeps them functioning smoothly. They are a must-have for both professional and home workshops, ensuring precise and secure clamping every time.

Types of Saws

Saws are categorized into hand saws, power saws, and specialty saws. Each type offers unique features for cutting materials, ensuring versatility and precision in woodworking and metalworking projects.

3.1 Hand Saws

Hand saws are versatile tools for precise cuts in woodworking. They come in various types, including rip saws for cutting with the grain and crosscut saws for cutting against it. Backsaws and doboku saws are ideal for fine, accurate cuts, while keyhole saws handle curved or irregular shapes. Proper technique ensures clean results, making hand saws indispensable for craftsmen seeking control and detail in their work. Regular sharpening and maintenance keep them efficient and long-lasting.

3.2 Power Saws

Power saws are versatile tools designed for efficient cutting in various materials. Circular saws excel at straight cuts in wood and metal, while jigsaws handle curved or irregular shapes. Reciprocating saws are ideal for demolition and tight spaces, and miter saws deliver precise angled cuts. These tools save time and effort, making them essential for professionals and DIYers alike. Proper blade selection and regular maintenance ensure optimal performance and safety. Always follow safety guidelines to avoid accidents and achieve clean, accurate results.

3.3 Specialty Saws

Specialty saws are designed for unique cutting tasks, offering precision and versatility. Scroll saws excel at intricate curves and detailed work, while coping saws handle small, tight spaces. Tile saws are optimized for cutting ceramic, marble, and glass. Each type features specialized blades or mechanisms, such as adjustable angles or diamond-coated edges, to tackle specific materials and projects. These tools are indispensable for professionals and DIYers seeking to achieve precise, customized cuts in challenging or artistic applications.

Using Clamps Effectively

Clamps are essential for securing materials safely. They hold materials tightly, preventing unwanted movement during cutting or gluing. Proper usage ensures accuracy and protects workpieces from damage.

4.1 Safety Tips for Clamp Usage

Using clamps safely is crucial to prevent accidents and ensure secure material handling. Always position clamps correctly to avoid slippage. Use the right clamp size and type for the material to prevent damage. Tighten clamps gradually and avoid over-tightening, which can cause injury or material breakage. Wear protective gloves when handling clamps. Ensure the workpiece is stable and properly aligned before applying clamps. Never leave clamps unattended while in use. Regularly inspect clamps for wear or damage. Proper clamp usage enhances safety and project success.

4.2 Best Practices for Securing Materials

Securing materials effectively ensures accuracy and prevents damage. Always use clamps of appropriate size and type for the material. Position clamps evenly to distribute pressure, avoiding uneven stress. Use protective pads to prevent surface damage. Align materials properly before clamping to maintain precision. For complex shapes, consider using jigs or fixtures. Ensure the workpiece is flat and stable on the work surface. Double-check materials for defects before clamping. Regularly inspect clamps for wear to maintain reliability. Proper material securing enhances project outcomes and minimizes errors.

Using Saws Effectively

Using saws effectively requires proper techniques, blade maintenance, and material alignment. Always ensure the saw is sharp and well-maintained for precise, clean cuts and optimal performance.

5.1 Sawing Techniques for Precision

Mastering precise sawing techniques is crucial for achieving smooth cuts. Use steady, consistent strokes to maintain control; Align the blade with marked lines and keep the workpiece secure. Apply gentle pressure for hand saws and proper feed rates for power saws. Regularly inspect blades for sharpness and adjust angles to suit the material. Correct posture and a well-lit workspace enhance accuracy. Practice these methods to ensure clean, professional results in every project.

5.2 Maintenance and Sharpening of Saws

Proper maintenance and sharpening of saws ensure optimal performance and longevity. Regularly clean blades to remove debris and apply lubricants to reduce friction. Sharpen saw teeth using files or sharpening tools, maintaining the correct angle and rhythm. Store saws in dry environments to prevent rust. For power saws, check and replace worn blades, and ensure proper alignment. Regular maintenance enhances cutting efficiency and accuracy, preventing blade dullness and binding issues. A well-maintained saw delivers precise cuts and extends its lifespan.

Workshop Setup and Organization

A well-organized workshop enhances efficiency and safety. Designate zones for cutting, clamping, and storage. Use tool racks, bins, and pegboards to keep clamps and saws accessible, reducing workflow disruptions.

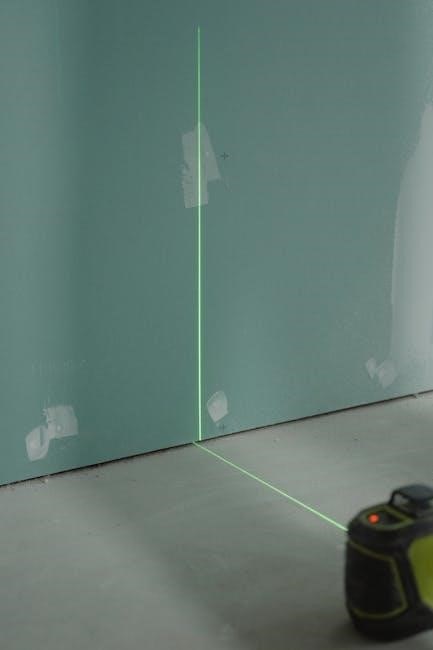

6.1 Setting Up a Workspace for Clamping and Cutting

Organizing your workspace is critical for efficient clamping and cutting. Position your workbench centrally, ensuring ample space around it for easy material handling. Install a sturdy vice on the bench for secure clamping. Place saws and clamps within easy reach to minimize movement. Use storage bins or racks to keep tools tidy, preventing accidents and saving time. A well-lit area with proper ventilation is essential for precision and safety during woodworking tasks.

6.2 Using Jigs and Fixtures for Accuracy

Jigs and fixtures are indispensable for achieving precise cuts and clamp placements. A jig acts as a template, guiding tools along predefined paths, while fixtures hold materials firmly in place. Both tools minimize human error, ensuring consistent results. For instance, a bench hook jig aids in cutting small pieces accurately, while a miter saw fixture ensures perfect angled cuts. Using these tools streamlines workflows and enhances overall project quality, especially in repetitive tasks or complex designs.

Advanced Techniques

Advanced techniques involve combining clamps and saws for intricate projects, such as angled cuts or multi-piece assemblies. Custom solutions enhance precision and efficiency in woodworking tasks.

7.1 Combining Clamps and Saws for Complex Projects

Combining clamps and saws enables precise execution of intricate cuts and joints. For angled cuts, use clamps to secure materials at desired angles while sawing. Multi-piece assemblies benefit from clamps holding components in place during cutting. Custom fixtures can enhance stability for complex shapes. This synergy ensures accuracy and reduces waste. Advanced techniques like compound angle cuts or curved sawing require meticulous clamp placement. Proper alignment and tight clamping are crucial for professional results. These methods elevate project complexity and quality, making clamps and saws indispensable in advanced woodworking.

7.2 Custom Clamp and Saw Solutions

Custom clamp and saw solutions cater to unique project needs. Adjustable clamps with modular jaws offer versatility for irregular shapes. Saws can be modified with custom blades for specific materials. DIY fixtures, like angled clamping jigs, enhance precision. Combining 3D printed parts with traditional clamps creates tailored setups. These solutions optimize workflow, reduce material waste, and improve accuracy. They are ideal for intricate designs and unconventional materials, ensuring projects meet exact specifications and exceed quality expectations. Customization empowers creators to overcome limitations and achieve exceptional results.

Troubleshooting Common Issues

Identify root causes of clamp slippage and saw blade dullness. Regular maintenance and proper alignment can prevent issues. Adjust tools for optimal performance and material compatibility.

8.1 Solving Clamp Slippage and Alignment Problems

Clamp slippage often occurs due to worn pads or uneven surfaces. Replace worn pads and ensure materials are clean. For alignment issues, use a reference fence or guide to maintain accuracy. Tighten clamps gradually, starting from the center to avoid skewing. Regularly inspect and maintain clamps to prevent misalignment. Proper setup and even pressure distribution are key to achieving secure holds without slippage or misalignment.

- Use non-slip materials between clamps and workpieces.

- Check for clamp wear and tear periodically.

- Ensure surfaces are clean and dry before clamping.

8.2 Addressing Saw Blade Dullness and Binding

Dull saw blades and binding issues hinder productivity and accuracy. Regular sharpening or replacing blades ensures optimal performance. Proper blade alignment and maintaining the correct tension are crucial. Use the right blade type for your material to prevent overheating. Clean sawdust and debris regularly to avoid friction. Apply lubricants like wax or oil to reduce binding. Always follow manufacturer guidelines for maintenance to extend blade life and ensure smooth cutting operations.

- Sharpen or replace blades when cutting becomes difficult.

- Check alignment and adjust as needed.

- Use appropriate blade types for materials.